|

| Headquarter of Entire Factory |

|

|

|

| Office Building |

Entrance |

Orthopedics Division |

|

|

|

Research and

development department |

Sample room |

Front gate |

Waston orthopedics division lies in the Wujin High-Tech industrial Park, covering the area of nearly 70, 000 square meters. We have the standard factory of 35,000 square meters, cleaning room of 1,000 square meters, and research centre of 3,000 square meters. There are two production bases in our company. One has been put into use at the end of 2005. Another one with the building coverage of more than 20, 000 square meters, is mainly used for developing and producing the surgical staplers.

|

|

| Ultrasonic Welding Machine |

Ultrasonic Fine Cleaning and Drying Cabinet |

|

|

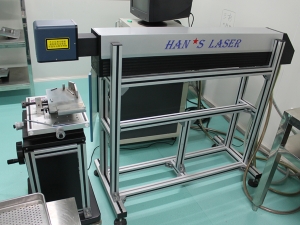

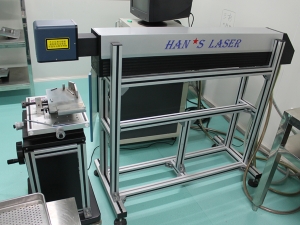

| Laser Labeling Machine |

Automatic After-treatment Line---Cleaning, Electrolyzing, and Passivating |

|

|

| Inspection |

Cleaning Shop |

|

|

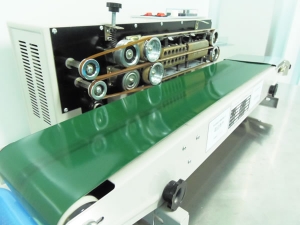

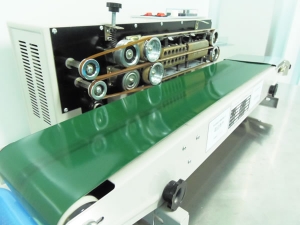

| Automatic Sealing Machine |

Deionized Water |

The orthopaedic division is responsible for researching, developing the products used for the internal fixation. The products consist of artificial joint, and the series separately used for spine, trauma.

|

|

| Hass CNC Machine |

DECKEL MAHO Germany |

|

|

| TRANSCEND |

German Chiron FZ15S-5 Axis Processing Centre |

|

|

| Japanese STAR Automatic Lathes |

Processing |

Most of the machines are the high precision numerical control equipment that work automatically. There are more than 200 sets, including German DMG, CHIRON, and America HASS fix axis processing centers, Japanese STAR Automatic Lathes, and so on. We also have the inspection equipment and measuring instruments.

|

|

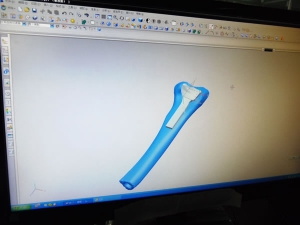

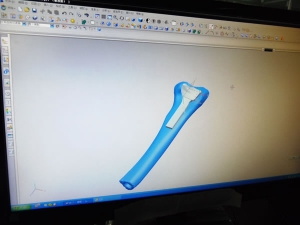

| Product Designed through the Software |

Mould |

|

|

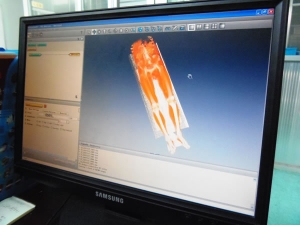

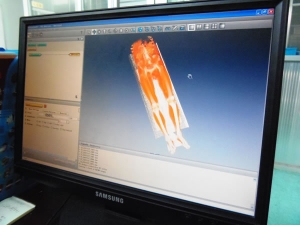

| Three-dimensional Animation Design |

|